Garage Openers - PFC CONTROLS | Miami, Gate Operators, Sliding Gate, Swing Gate, Intercoms, Turnstiles, Bollards, Barrier gate

- GATE ACCESS

- PEDESTRIAN ACCESS

- CONTACT US

- Main Menu

- GATE ACCESS

- PEDESTRIAN ACCESS

- CONTACT US

Why Choose a Roll Lamination Machine for Your Business?

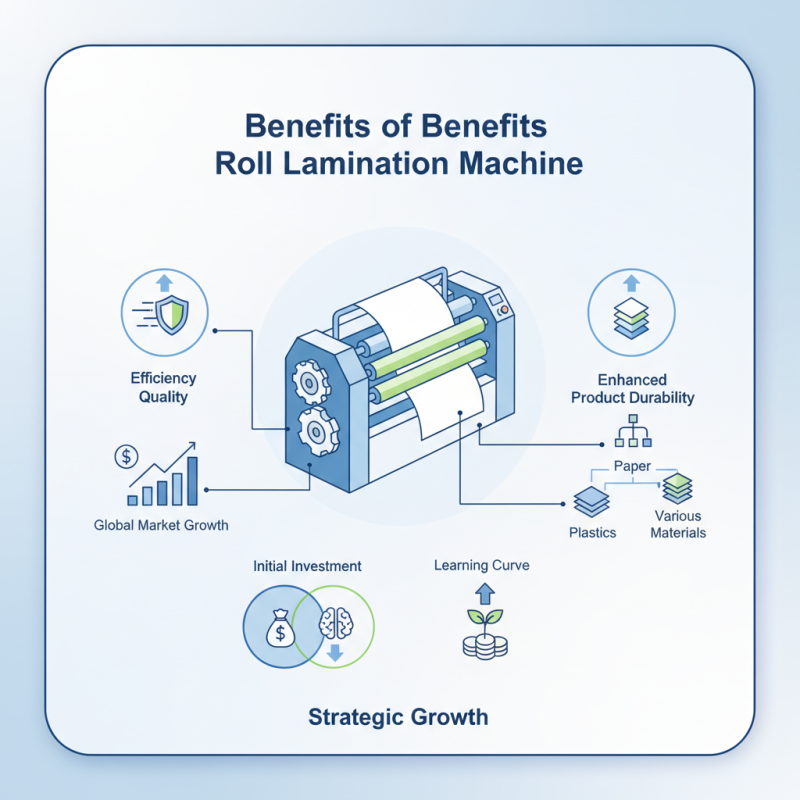

In today’s competitive market, businesses must invest wisely in their production processes. A Roll Lamination Machine is an essential tool for companies seeking efficiency and quality. According to a recent industry report by Smithers Pira, the global laminating market is estimated to reach $24 billion by 2025. This data highlights the growing demand for lamination technologies across various sectors.

Using a Roll Lamination Machine can streamline operations and enhance product durability. With the increasing need for protective packaging, businesses must consider equipment that adapts to their specific needs. The versatility of these machines allows for various materials, from paper to plastics, ensuring flexibility in production. However, potential challenges exist. Companies may face initial investment costs and learning curves that can impact profitability.

Investing in a Roll Lamination Machine is not just about acquiring equipment; it’s also about strategic growth. As market demands evolve, businesses must reflect on how they can leverage technology to stay ahead. The future of lamination seems promising, yet it calls for careful planning and adaptation.

Understanding Roll Lamination Machines and Their Functionality

Roll lamination machines play a crucial role in various industries. They provide a reliable way to protect and enhance documents, images, and food packaging. These machines allow for a consistent and high-quality finish. According to a report by Smithers Pira, the global laminating machine market is expected to grow by 5% annually through 2025. This growth highlights the increasing demand for lamination solutions.

The functionality of roll lamination machines is straightforward yet effective. They use heat and pressure to bond layers of materials together. This method ensures durability and resistance to wear and tear. Additionally, roll lamination is efficient, allowing higher production rates than traditional methods. Many businesses benefit from saving time and costs with these machines.

**Tip:** Regular maintenance is key. Cleaning rollers and checking temperature settings can prevent potential issues.

Despite their advantages, there are challenges. Operator training is essential for optimal machine use. Misalignment can lead to waste and inefficiency. It's important to ensure proper setup during operations.

**Tip:** Always conduct a test run before full production. This small step can save time and material.

Understanding these machines will help businesses make informed decisions. Investing in a roll lamination machine can lead to significant benefits, provided that the challenges are addressed.

Why Choose a Roll Lamination Machine for Your Business?

| Feature | Description | Benefits |

|---|---|---|

| Speed | High-speed lamination process capable of handling large volumes. | Increased productivity and efficiency in operations. |

| Versatility | Can laminate various materials including paper, photos, and cards. | Adaptable to different business needs and applications. |

| Durability | Creates a protective layer that is resistant to tearing and moisture. | Prolongs the lifespan of materials and products. |

| Consistency | Provides uniform lamination across all products. | Ensures high-quality output and eliminates wastage. |

| Cost-Effective | Reduces labor costs by automating the lamination process. | Maximizes return on investment (ROI) for businesses. |

Benefits of Using Roll Lamination Machines in Business Operations

Roll lamination machines offer multiple advantages for businesses looking to enhance their operations. They provide a protective layer to documents, ensuring durability and a professional finish. According to a report by Smithers Pira, the demand for laminating equipment has grown by 5% annually. This growth reflects the increasing need for high-quality materials in various industries.

Using roll lamination can improve efficiency in production. Businesses can laminate large volumes quickly, reducing turnaround time. For instance, a company that previously used sheet lamination might find that roll lamination nearly doubles their output. Yet, some businesses may overlook the potential complexity of setting up these machines. It's essential to invest time in training staff to maximize effectiveness.

Furthermore, roll lamination is cost-effective in the long run. The initial investment can seem high, but the reduction in material waste offsets these costs. A study indicated that businesses save about 20% on material costs when opting for roll lamination over traditional methods. However, this requires regular maintenance and a clear understanding of operational needs, which some businesses may not fully grasp. Adjusting to this transition can prove challenging.

Comparative Analysis: Roll Lamination vs. Other Laminating Methods

Roll lamination machines stand out among laminating methods due to their efficiency. They can handle large volumes quickly, which is a plus for busy businesses. With this method, the lamination process is smooth and uniform. Roll lamination is ideal for protecting banners, posters, and other printed materials. Many users note the crisp finish it provides, giving products a professional look.

In contrast, pouch laminating machines are slower and more labor-intensive. They suit smaller jobs but may not meet high demand. Cold laminating is another option, but it lacks the durability that roll lamination offers. Some find cold lamination easier and cheaper. However, the trade-off is often a lesser quality finish. There are lots of factors to consider when choosing a method, raising questions about efficiency and cost.

Businesses must evaluate their specific needs. Additionally, the long-term durability of materials is crucial. Relying solely on one method can be limiting. Balancing speed and quality is essential. It’s not just about choice; it’s about finding the right fit for your goals. Each method has its pros and cons, and reflection is necessary for making informed decisions.

Why Choose a Roll Lamination Machine for Your Business?

Key Features to Consider When Choosing a Roll Lamination Machine

When choosing a roll lamination machine, consider its features carefully. The type of laminating film matters. You can opt for either standard or specialty films. Specialty films provide extra protection. Think about your specific needs.

Tip: Assess the thickness of the materials you’ll be laminating. Different machines handle varying thickness levels. If you plan to laminate thick documents, ensure the machine can accommodate them.

Another crucial feature is the speed of the lamination process. Faster machines save time in production. However, too much speed can lead to errors. Calibration might become a frequent task.

Tip: Test the machine before making a purchase. Check for consistent results and ease of use. User-friendly controls can make a big difference in day-to-day operations. Remember, a machine that seems perfect today may not meet future needs. Stay flexible and open to change.

Cost-Effectiveness and Long-term Value of Roll Lamination Solutions

Roll lamination machines offer significant cost-effectiveness and long-term value for businesses. Data shows that companies using roll lamination can save up to 30% in material costs. This is due to reduced waste during production. Industries such as packaging and graphic printing have reported enhanced durability in their products, with lamination extending shelf life by an average of 50%. This means less frequent reprinting and restocking.

The initial investment in a roll lamination machine might seem high. However, the longevity of laminated products justifies the expense. According to industry reports, businesses can see a return on investment within 12 to 18 months. The reduction in replacement costs alone can offset the initial outlay. Furthermore, laminated items resist moisture and UV damage. This durability can lead to long-term savings that outweigh short-term financial concerns.

Nevertheless, businesses must consider the learning curve associated with new equipment. The transition may require training staff, leading to temporary inefficiencies. Companies must also balance the demand for laminated products with production capabilities. It's essential to assess the unique needs of the business. Choosing the right lamination solution shouldn't be rushed. Each option comes with its own set of challenges and benefits.